I didn't want to spend much money on this project, so I took inventory of what I had on hand. I had about 3/4 of a sheet of 1/4 inch plywood with a nice looking veneer layer leftover from the back of the cd cabinet, as well as some random wood of unknown species leftover from a futon frame I disassembled a while back. I also had pine construction lumber, as usual. With these ingredients, I decided to do something loosely inspired by the construction style John Heisz used on his Chop Saw Station a while back. He used thin plywood, stiffened up with solid wood edging. I did the same thing with this little shelving unit.

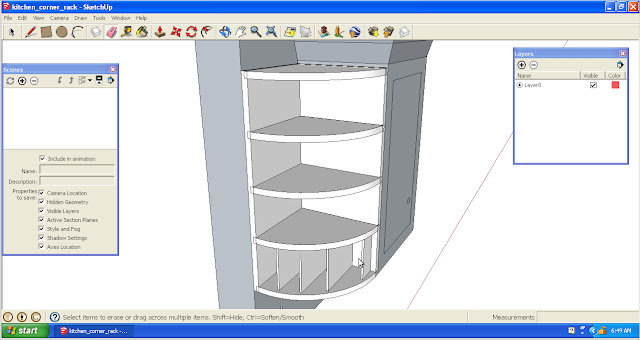

As usual, I started out by mocking this up in sketchup:

Sketchup file.

I first made up my edging. All of it is 3/4 inch thick and 1 1/2 inches wide. I used the leftover futon wood for the shorter pieces of edging, and the pine construction lumber for the longer pieces. I ripped some 2x4s vertically to yield 1 piece about 7/8" thick by 3 1/2 inches wide, and another piece about 9/16" thick by 3 1/2 inches wide. The remaining thickness is lost to the tablesaw blade. Construction lumber often needs a little jointing before this type of ripping operation, and this time was no exception. After that, I set my saw to about 1 11/16" height (about 1/16" less than half the full thickness of the wood I'm cutting), and rip it in two passes. This leaves the 2 halves of the board attached by a little 1/16" strip, which keeps them together and makes things a little more stable while ripping such long boards. Then I just split them apart with a chisel driven into the edge of the little strip that connects them and plane the 7/8" thick half down to 3/4" thick.

I planed off some finish that was on the futon wood and got it down to the same thickness as the pine edging. I cut everything down to final size, and then rabbetted all the edging to receive the plywood panels on my table saw with a dado blade.

Then I notched out all the long pieces of edging to receive the shorter pieces.

I ripped all the plywood panels to size, and assembled all the sub assemblies by gluing the edging to the plywood panels.

I should have made the rabbets in the edging to receive the back panel before I assembled all the panel and edging assemblies, but I forgot and had to make these rabbets after gluing the edging on.

Since this shelving unit is not intended to carry a heavy load on the shelves, I decided to do the final assembly with pocket hole screws and glue. I drilled pocket holes in the ends of the shelf assemblies.

Then I realized I needed another filler strip of the edging wood to provide a place for the pocket hole screws on the middle shelf to attach to the end assemblies. I made some pieces out of pine, and glued them to the plywood and edging on the end assemblies. Then I put glue on the ends of the shelves, and drove the pocket hole screws in place. I attached the back panel with glue and some small brads with my brad nailer. I drilled out a hole for cords to pass through the back panel before I glued this panel in place.

Then I realized I needed another filler strip of the edging wood to provide a place for the pocket hole screws on the middle shelf to attach to the end assemblies. I made some pieces out of pine, and glued them to the plywood and edging on the end assemblies. Then I put glue on the ends of the shelves, and drove the pocket hole screws in place. I attached the back panel with glue and some small brads with my brad nailer. I drilled out a hole for cords to pass through the back panel before I glued this panel in place.

I finished this project with a couple of coats of Danish Oil. I wanted something that would be relatively easy to apply, and I didn't need a lot of protection. Plus I already had this on hand.

Here's the completed shelving unit in place.